Introduction

Akik Dye Chem – Disperse Dyestuff are an exclusive range of Azo, Anthraquinone, Coumarine, Methine, and Quinoline based Disperse Dyes, suitable for dyeing and printing materials made of polyester fiber and its blend.

Selected Akik Dye Chem dyes can also be applied on nylon and acetate fiber materials.

Akik Dye Chem dyes are characterized by excellent dispersion and good all-around fastness properties.

Akik Dye Chem range includes disperse dyes having different degrees of sublimation fastness and hence dyer/printer has a wide choice of selection of dyes according to their requirements.

This catalogue contains comprehensive information on various applications of dyes into several types of substrate (fabric) and fastness properties that can be obtained in the depth of shade illustrated.

Akik Dye Chem products illustrated in this booklet meet requirements of German Eco Laws.

Classification of Akik Dye Chem Dyes

S Indicates High Energy Dyes:

- High sublimation fast dyes.

- Suitable for Print, Pad, High temperature or high pressure steam fixation.

- Suitable for Thermosol dyeing.

- Suitable for yarn, fibre and fabric dyeing.

SE Indicates Medium Energy Dyes:

- Good to moderate sublimation fastness.

- Suitable for selective application on polyester & its blend.

E Indicates Low Energy Dyes:

- Good leveling property.

- Low sublimation fast dyes.

- Suitable for piece dyeing of polyester / blend / Acetate fiber / Nylon.

Commercial form of Akik Dye Chem Dyes

Akik Dye Chem Dyes are supplied in the form of powder only.

To minimize dusting, we give anti-dusting treatment to almost all dyes being produced by us, by the means of online blending along with anti-dusting treatment.

We provide low dusting and homogeneous quality of dyes to the customers.

Dispersion of Akik Dye Chem Dyes

Akik Dye Chem dyes are slowly sprinkled in ten times of its weight of soft warm water (40°-50°C) under slow stirring.

The dye dispersion should be sieved through fine cloth / fine sieve prior to application.

Application Method

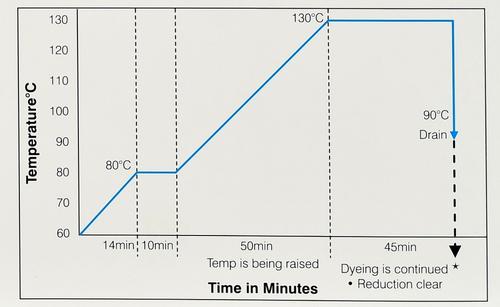

1.1 Exhaust Dyeing at 130°C (HTHP Condition)

Dye bath addition:

| X % | Akik Dye Chem Pre-Dispersed Dyes |

|---|---|

| 1 g/l | Dispersing Agent |

| 0.5 - 1 g/l | Leveling Agent |

| 0.5 g/l | Water Softener |

| Y g/l | Acetic Acid for pH 4.5 - 5.0 |

Dyeing Parameters:

- Fabric to be dyed must be free from chemical, proper pre-treatment should be given and pH of fabric should be 4.5 to 5.5.

- M:L Ratio 1:10.

- pH 4.5 – 5.0.

- 60°C to 80°C @ 1.5°C/min [In 14 minutes].

- At 80°C hold time 10min.

- 80°C to 130°C @ 1°C/min [In 50 minutes].

- Dyeing at 130°C for 20 – 60 minutes depending on depth of shade.

- Cool the dye bath upto 90°C @ 4°C/min [In 10 minutes].

- Drain the dye bath and dyed goods should be rinsed with hot water and reduction cleared as per procedure.

Normal Dyeing Cycle: